Make Weigh-Tech Your Turnkey Solution Provider – from Design to Daily Operation

Whether you are starting from a rough idea and a greenfield situation or you have already been in operation and just looking for a revamp, Weigh-Tech is there with you throughout the process. Our team of highly experienced engineers and designers know the questions to ask to help you develop your ideal facility.

From design through fabrication and erection, our knowledgeable staff guides your product into place. We care for you and your equipment after the sale as well, with training manuals, operator training online, or at your facility, and re-certification and safety audits to ensure your ongoing delight.

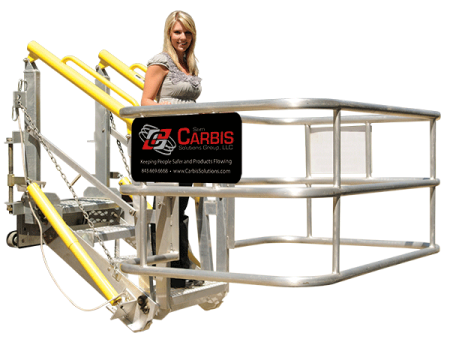

Weigh-Tech provides Sam Carbis Solutions Group, LLC:

- Complete design and engineering to help make your dream a reality

- Custom Fabrication to meet your unique requirements

- Online or On-site training available to teach your operators how to operate the new equipment

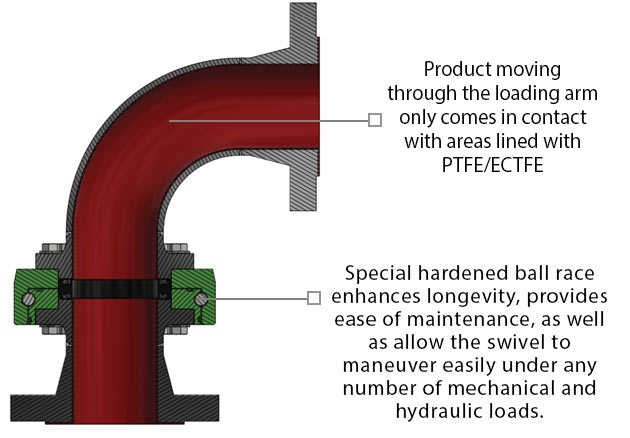

- Full loading arm and/or spill containment integration

- Annualized recertification programs to ensure operator safety and loading spot efficiency for years to come

Improve Safety While Increasing Productivity!

Improve Safety While Increasing Productivity!

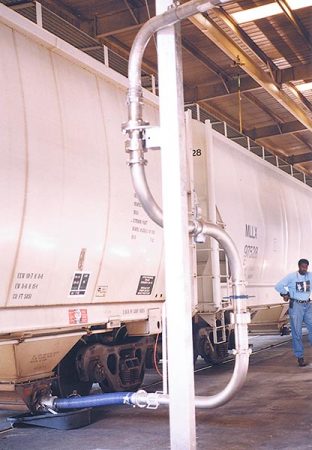

The safety of the loading arm operator is the prime advantage since they remain on the ground – not on top of the vehicle where falls are a common threat. Connections are made more quickly so overall loading time is reduced.

The safety of the loading arm operator is the prime advantage since they remain on the ground – not on top of the vehicle where falls are a common threat. Connections are made more quickly so overall loading time is reduced.

Designed for your specific application, our truck safety cages feature:

Designed for your specific application, our truck safety cages feature:

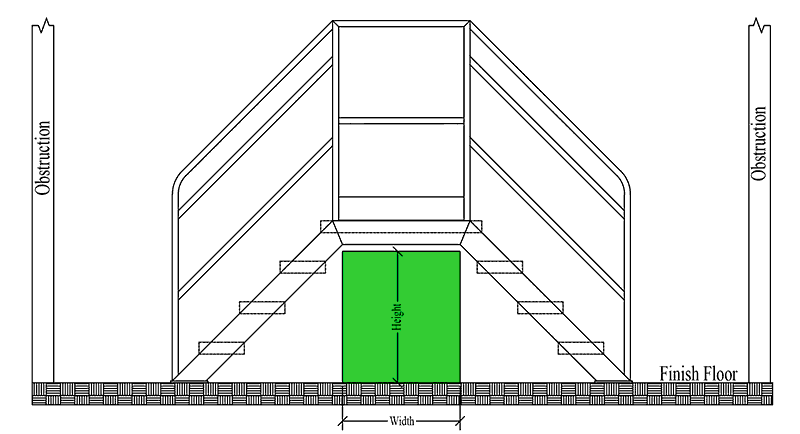

The TCG 2500 telescoping gangway offers significant fall prevention in vehicles of varying widths. As well as:

The TCG 2500 telescoping gangway offers significant fall prevention in vehicles of varying widths. As well as: An Important Note On Railcar Fall Protection

An Important Note On Railcar Fall Protection

All Carbis Gangways and Ramps Offer:

All Carbis Gangways and Ramps Offer: