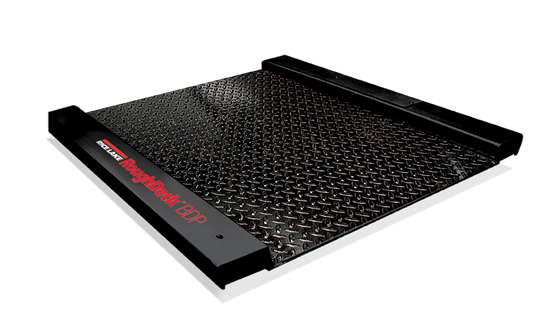

Pit Style Hydraulic Dock Leveler

The LHP Series dock leveler combines cost-effective hydraulic technology with our efficient deck and frame design to produce a reliable, price sensitive hydraulic dock leveler. The structure of the LHP incorporates box construction deck with an efficient deck and frame design. LHP levelers have added safety features and save valuable time in operation and maintenance.

LHP Series levelers come in 6’, 6’6”, & 7’ standard widths and 6’ & 8’standard lengths. Other lengths may be available upon request. Standard capacities for the LHP Series are 25K, 35K, 40K, CIR (Comparative Industry Rating).

Now available with iDoc Controls

• Simple Push Button Control

• Four Sided Box Construction

• Efficient Frame and Deck Design

• Full Hydraulic Lip Activation

• Velocity Safety Stop

• Lockout Tagout Maintenance Strut

• Night Locks/Cross Traffic Support

• Motor Overload Protection

• Low Maintenance Design

• Full Range Toe Guards

• Two (2) DB-13 Molded Rubber Bumpers

Information

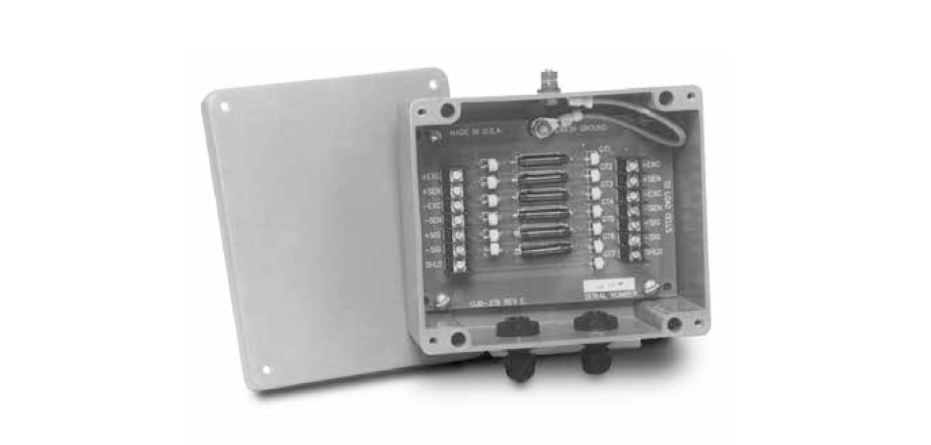

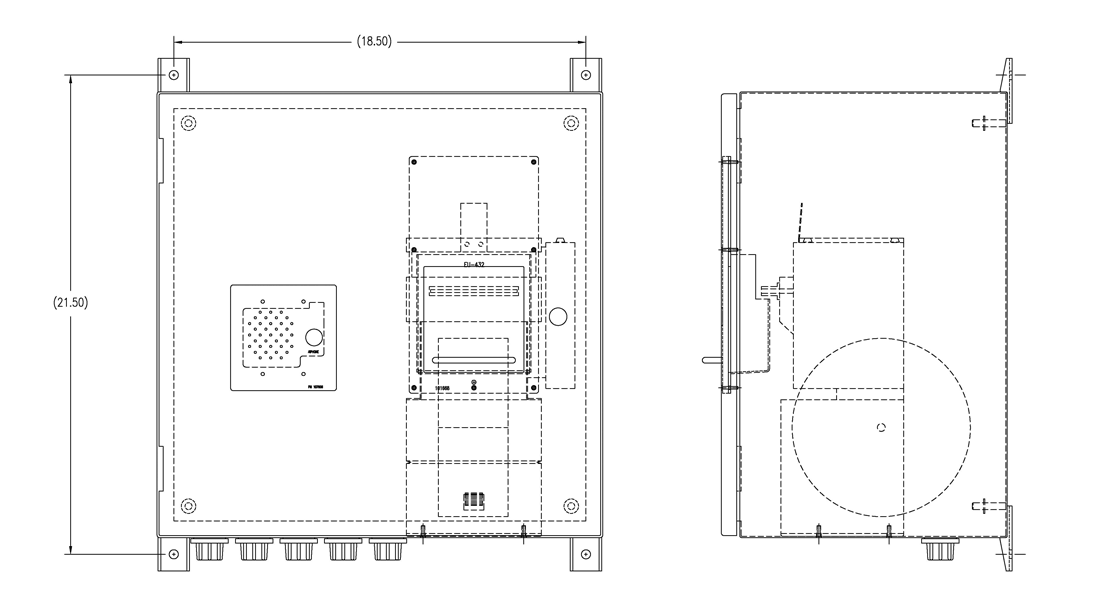

GENERAL DESCRIPTION

All POWERAMP® LHP Series hydraulic dock levelers incorporate the use of hydraulics to raise and lower both the platform and lip. A single push button activates a hydraulic pump for operating both lip and hoist cylinders. Systems, LLC is an active member of Loading Dock Equipment Manufacturers (LODEM), a product section of the Material Handling Industry. Unit conforms to OSHA, U.S. Department of Commerce Standard CS-202-56 and is manufactured in compliance with the American National Standard of Safety Performance and Testing of Dock Leveling Devices (ANSI) MH 30.1. Unit manufactured by Systems, LLC.

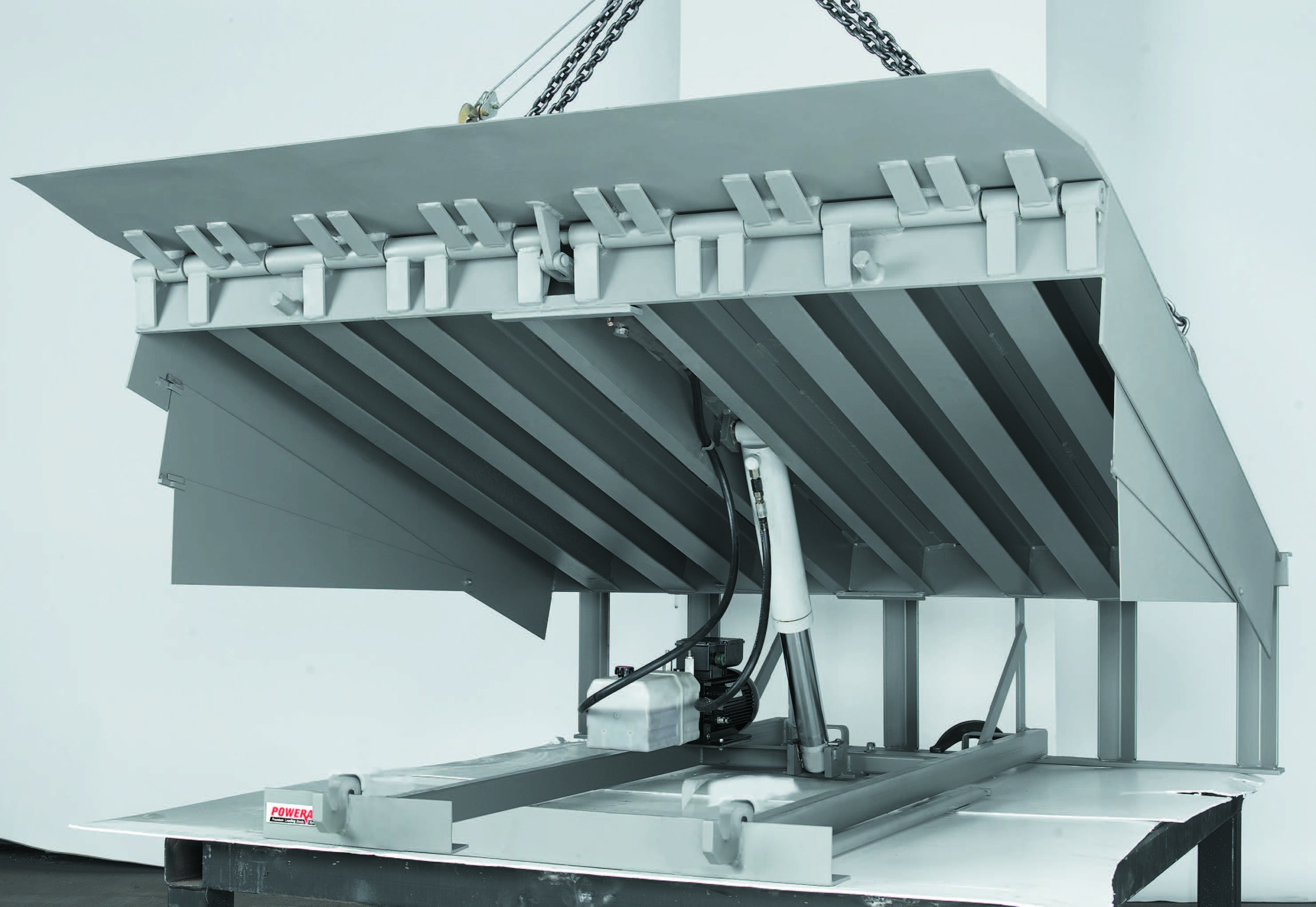

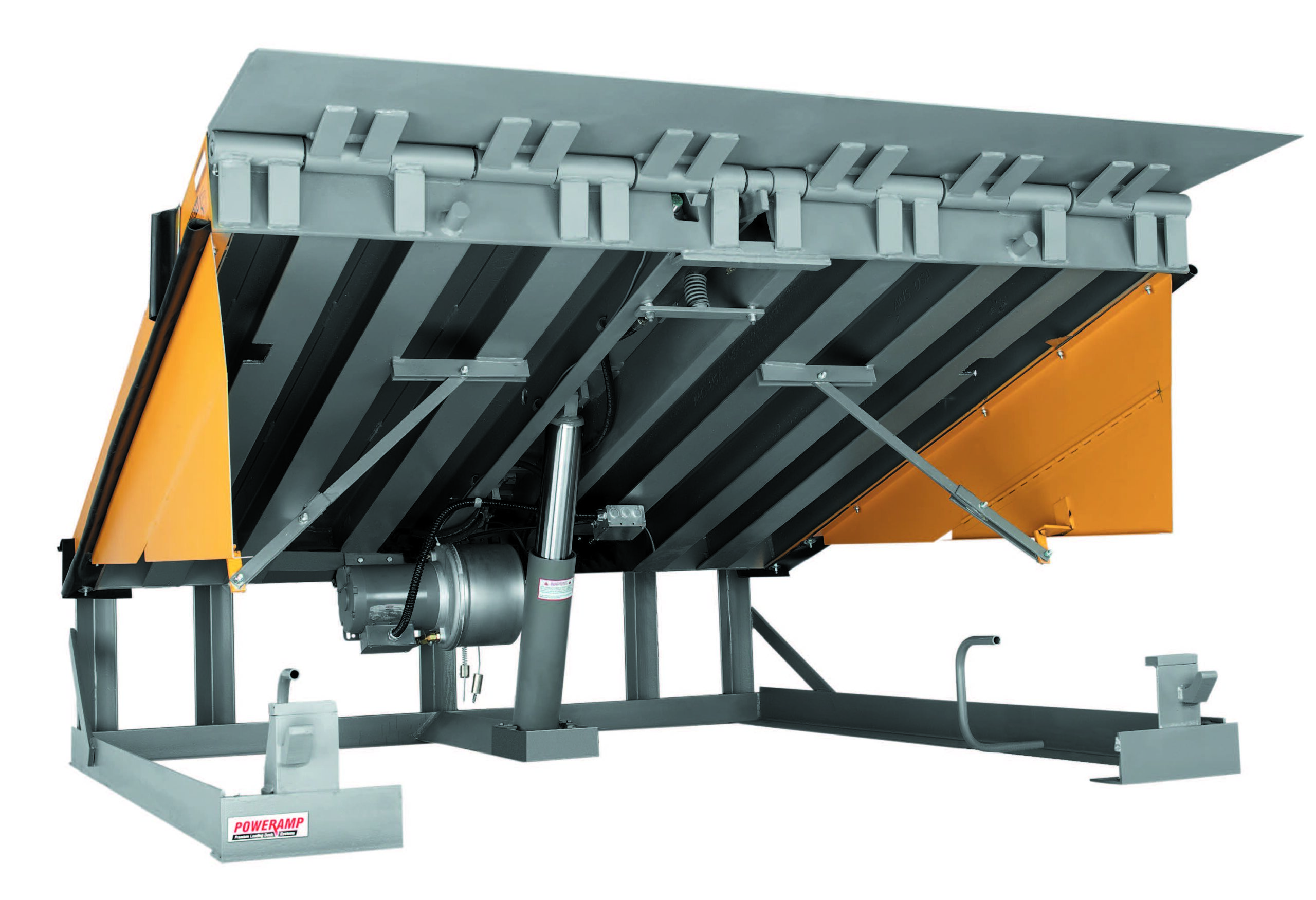

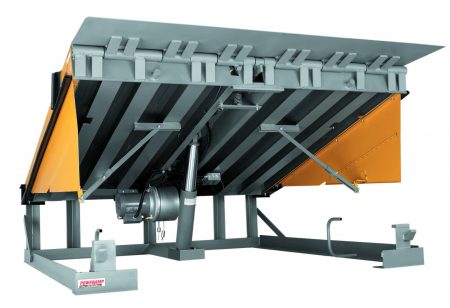

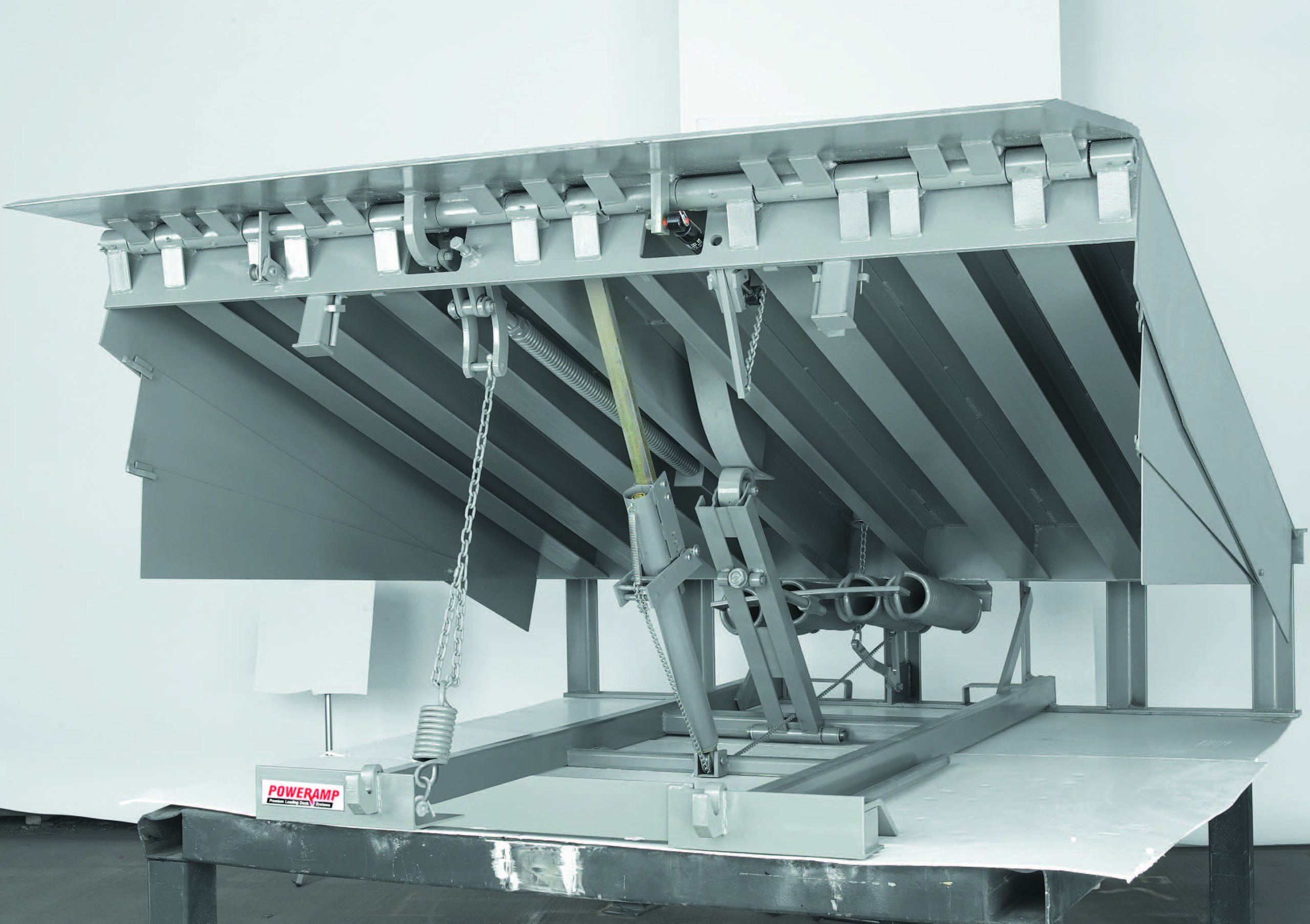

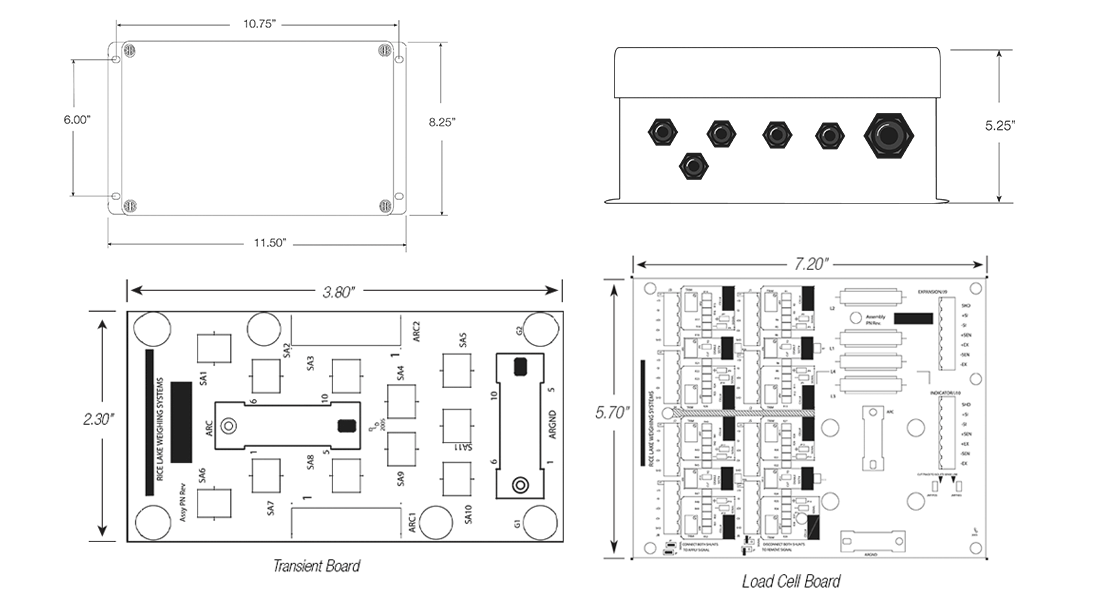

CONSTRUCTION

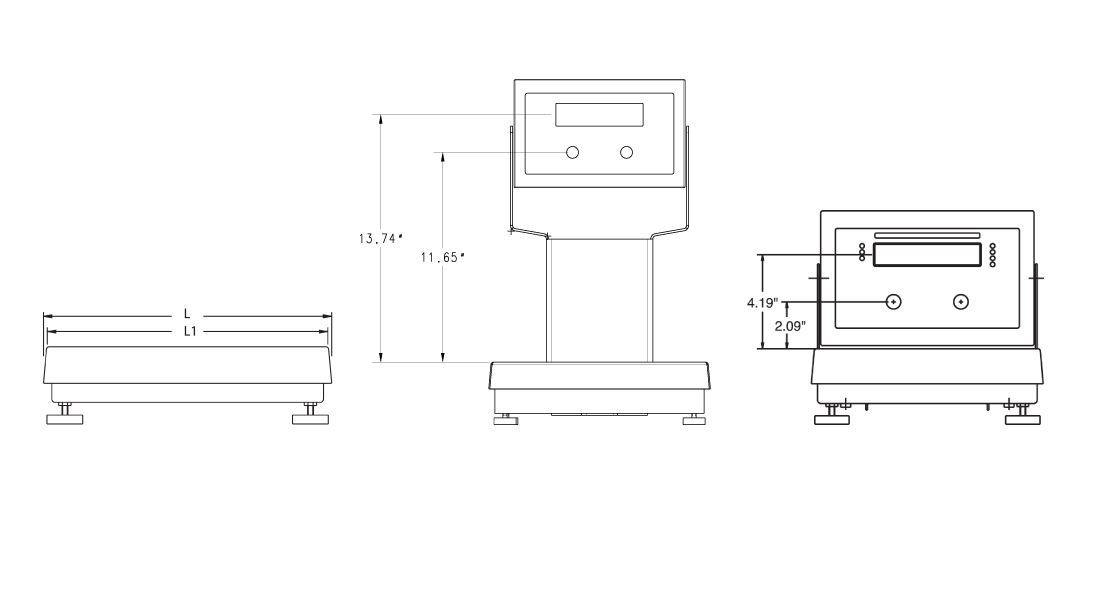

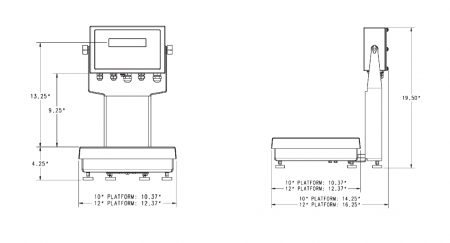

The platform is constructed of 1/4” thick 4-way high tensile 50,000 minimum yield A572 steel safety tread-plate. Platform is reinforced and supported by full-length 6” roll formed “C” channels for 25,000 and 35,000 lb CIR and 6” structural “C” channels for 40,000 lb. CIR capacity units. Front header plate is 1/2” x 7” hot rolled steel. POWERAMP LHP Series lips are made of 4-way safety tread-plate, the 25,000 lb CIR is 1/2” thick and the 35,000 and 40,000 lb CIR are 5/8” thick. The standard lip length is 16” on all capacities. Hinge tubes are 1 3/4” OD x 5/16” wall, 1 7/8” x 3/8” wall, or 2 1/8” x 1/2” wall depending upon CIR. All lip hinge pins are 1” M1044 steel. Steel joist gussets welded to front header are standard on all roll form “C” channels. All platforms are designed to compensate for up to 4” of canted truck beds.

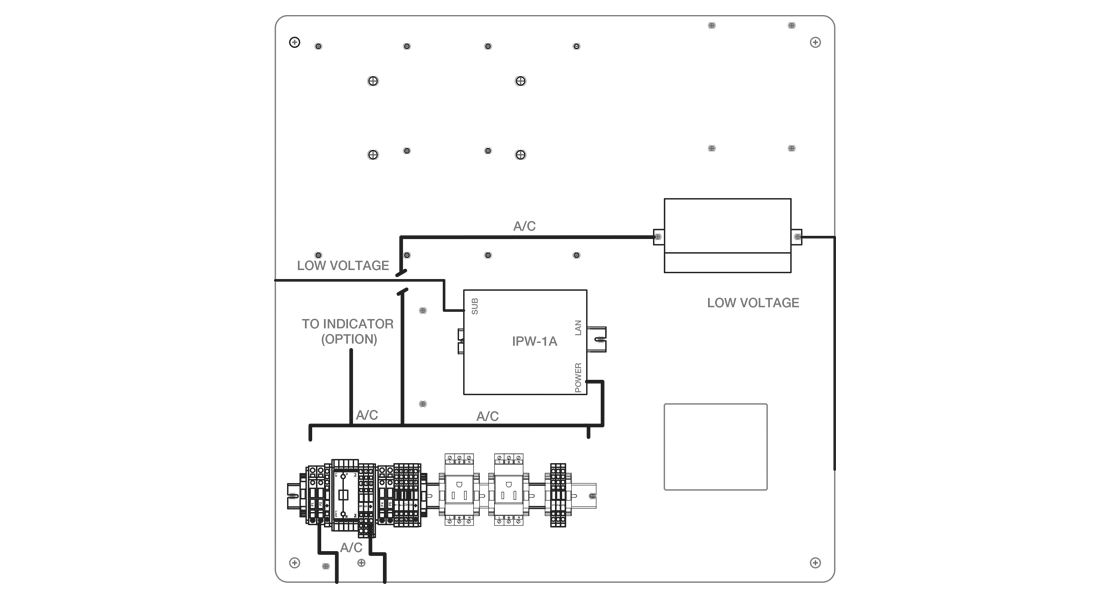

HYDRAULICS

Platform is raised by hydraulic cylinder, all hydraulic hoses are elevated under the leveler platform, away from debris. Hoist cylinder is hard chrome-plated single acting design with 2 1/2” OD rod and 3” ID bore. Hoist cylinder is equipped with a velocity safety stop to limit free fall of loaded platform to 3”(±1”). Lip operation is controlled by a hard chrome-plated cylinder having a 2” ID bore and is fully yieldable. Elevated, frame mounted pump and motor assembly keeps clear of debris accumulation in pit.

STANDARD OPERATIONAL FEATURES

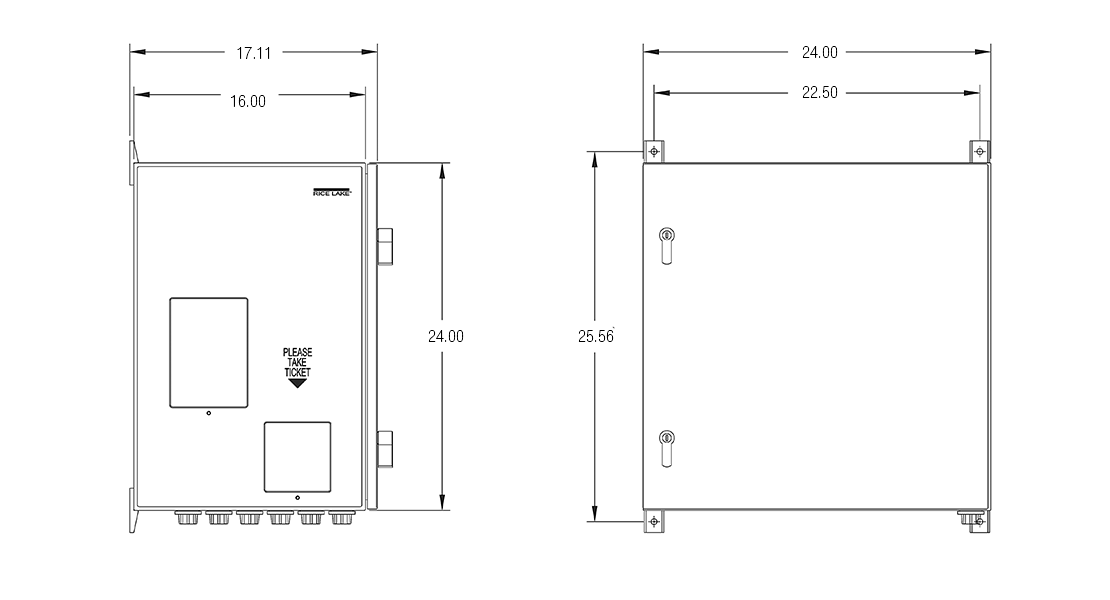

The LHP Series Leveler is controlled remotely from wall mounted control panel. An array of optional control panel features are available. Lip keepers welded to frame members provide nighttime security and cross-traffic support. Full operating range toe guards are provided as standard. Maintenance prop with ‘Lock-out Tag-out’ capability is provided as standard. Each LHP leveler is shipped with two (2) 4½” thick x 10”h x 14”w DB -13 molded bumpers as standard.

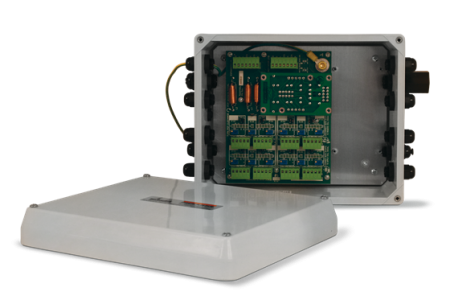

ELECTRICAL

Hydraulic pump motor shall be 1 1/4 HP TENVC at 115v single phase. Optional 3 Phase motors are available, consult factory. Electrical control panel is non-metallic Nema 4 enclosure for single push-button, or NEMA 4X for iDock™ Controls. All electrical components, connections and wiring are UL listed or recognized. Please Note: Unless specifically noted on quotation, all electrical requirements are the responsibility of others.

INSTALLATION

Units shipped completely assembled and ready for installation in preformed concrete pit. Pit construction to be in accordance with certified Systems, LLC pit detail drawings. Contact Systems, LLC for current cost and nearest distributor.

WARRANTY

All POWERAMP LHP Series models feature a full one (1) year base warranty on all structural, hydraulic and electrical parts, including freight and labor charges in accordance with Systems, LLC’s Standard Warranty Policy. Systems, LLC warrants all components to be free of defects in materials and workmanship, under normal use, during the warranty period. This base warranty period begins upon the completion of installation or the sixtieth (60th) day after shipment, whichever is earlier. Additional warranty extensions may be available upon approved submittal of application information.

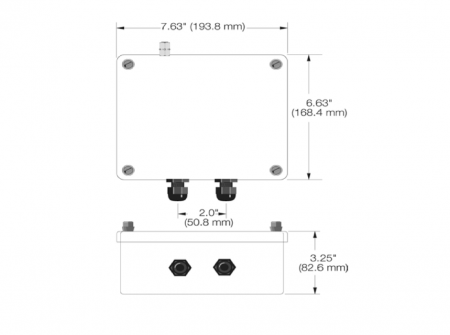

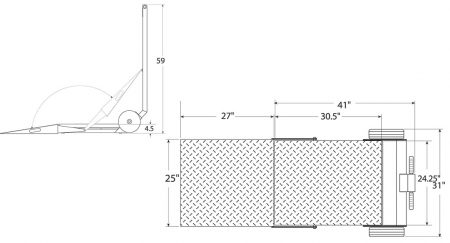

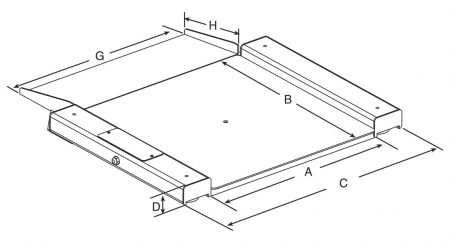

LHP Series Hydraulic Dock Leveler Dimensions:

MODEL – Normalize Size:

• LHP-66 6’ x 6’

• LHP-68 6’ x 8’

• LHP-656 6’6” x 6’

• LHP-658 6’6” x 8’

• LHP-76 7’ x 6’

• LHP-78 7’ x 8’

DYNAMIC COMPARATIVE CAPACITY INDUSTRY RATING:

• 12,500/25,000

• 17,500/35,000

• 20,000/40,000

LHP Series Hydraulic Dock Leveler Options:

• PowerHold® Restraint (S.C.)

• TPR® Restraint

• TPR UniLock® Restraint

• PowerStop® Restraint (manual) (S.C.)

• PowerStop® Restraint (automatic) (S.C.)

• Integrated Control Panel

• 18” Lip

• 20” Lip

• 3 Phase Motor Voltage

• Dock Alert Communication System

• iDock™ Controls

• 3-Wheel Lift Truck Protection

• Pit Steel (6 piece curb angle set)

• Pit Steel (4/angle,2/bumper)

• Pit Kit (3 sided)

• Pan Unit (4 sided)

• Foam Insulation

• Clean Sweep Frame

• Brush Weather seal

• Rubber Weather seal

• Lip Supporting Service Strut

• Laminated Bumpers B410-14

• Vertical Bumpers (laminated)

• 6” Thick Dock Bumpers

• Wheel Chocks Model #

• Dock Light (no bulb) Model #