CARBIS SOLUTIONS PTFE/ECTFE And Hastelloy® Loading Arms

April 7, 2021

CARBIS SOLUTIONS Railcar Dry Goods Loading

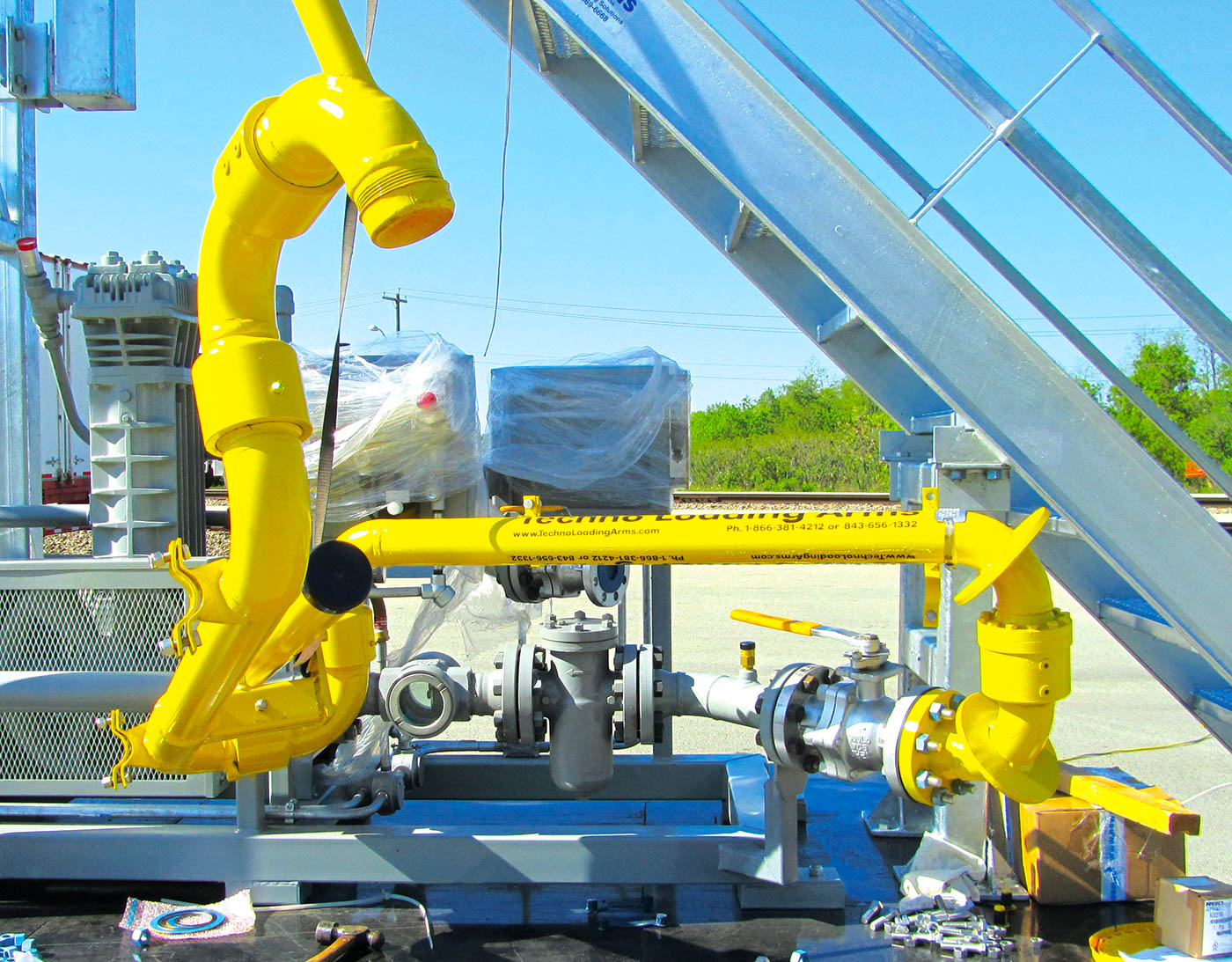

April 14, 2021CARBIS SOLUTIONS Bottom Loading Arms

Bottom loading arms offer numerous benefits over conventional top loading

The safety of the loading arm operator is the prime advantage since they remain on the ground – not on top of the vehicle where falls are a common threat. Connections are made more quickly so overall loading time is reduced.

The safety of the loading arm operator is the prime advantage since they remain on the ground – not on top of the vehicle where falls are a common threat. Connections are made more quickly so overall loading time is reduced.

Bottom loading systems also create less turbulence in the tank, reducing the danger of generating static electricity and can be easily adapted to recover vapors displaced during loading.

A few more benefits of bottom loading arms:

- Terminal tank truck bottom loading means tanks can be filled faster because a number of compartments can be loaded simultaneously

- Bottom loading islands are simpler and cheaper to build than top loading racks. You can realize more savings because you’ll safely load more material in a shorter time with less spillage and vapor loss.

- Improved safety by allowing the operator to remain on the ground during loading/unloading

- The ability to fill tanks faster since several compartments can be loaded simultaneously

FREE EDUCATIONAL DOWNLOADS

LOADING ARM BROCHURE

Let Weigh-Tech design the most efficient bottom loading arm for you.

Speed up tank truck loading—tanks can be filled faster when bottom loaded because a number of compartments can be loaded simultaneously.